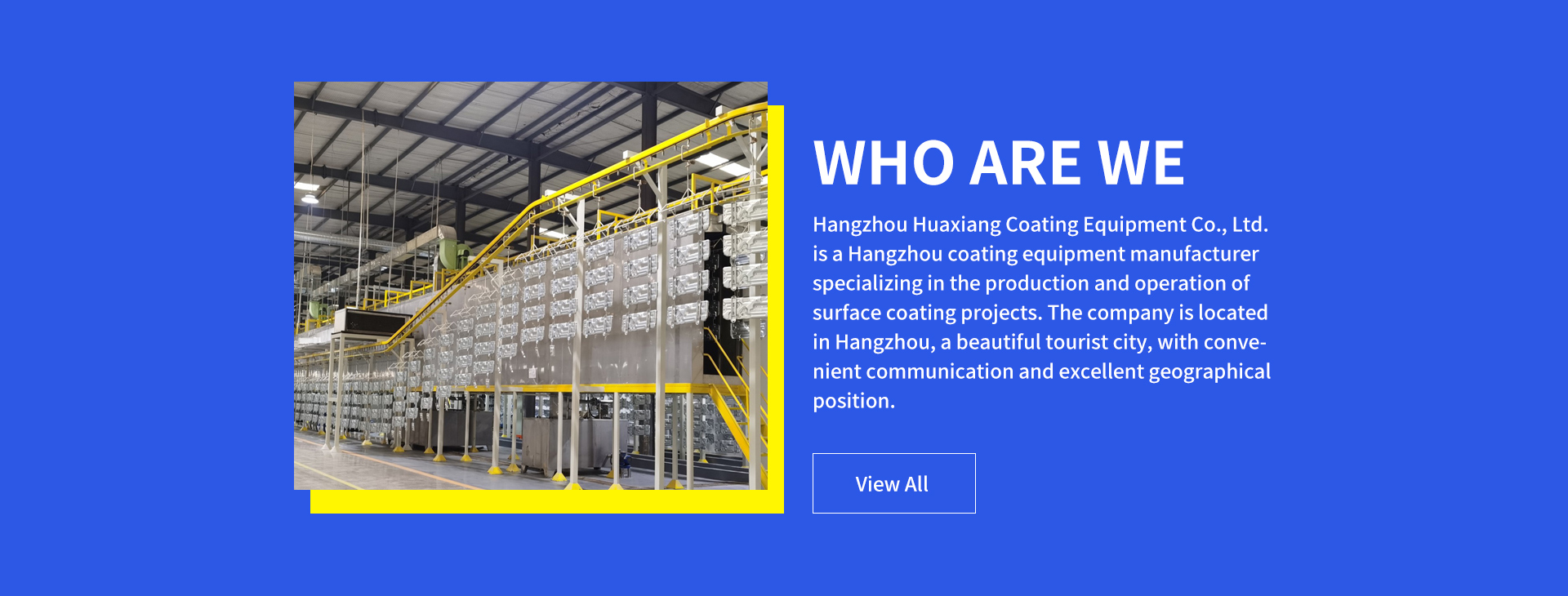

In the powder coating process, the

Powder Coating Curing Oven assumes a pivotal role in attaining a durable and high - quality finish. This treatise will comprehensively explore every significant dimension of this essential equipment.

A

Powder Coating Curing Oven represents a specialized heating apparatus engineered to effect the curing of powder coatings on diverse workpieces. It typically encompasses a heating chamber, heating elements, a temperature control system, and, in the case of continuous - type ovens, a conveyor system. The heating chamber furnishes a controlled environment conducive to the curing process. Heating elements, which can be either electrically - powered or gas - fired, generate the requisite heat to melt and fuse the powder coating. The temperature control system ensures that the oven maintains a precise and consistent temperature, a factor of paramount importance for the quality of the cured coating.

These curing ovens find extensive application across multiple industries. In the automotive parts manufacturing sector, they are employed to cure the powder coatings on engine components, wheels, and body trims, thereby providing long - lasting protection and an aesthetically appealing appearance. In the construction hardware industry, door handles, hinges, and other metal parts are subjected to curing in these ovens subsequent to powder coating, with the aim of enhancing their durability. The electrical appliance industry also derives benefits from

Powder Coating Curing Ovens, as they are utilized to cure the coatings on the outer shells of appliances such as refrigerators and washing machines.

The cost of a

Powder Coating Curing Oven varies in accordance with its dimensions, heating capacity, and incorporated features.

A small - scale, benchtop curing oven, suitable for hobbyists or small - scale workshops, may be priced in the range of $500 - $1500. These ovens typically possess basic heating functions and a relatively simple temperature control system. Mid - sized industrial curing ovens, characterized by larger heating chambers and more advanced temperature control mechanisms, may command a price range between $3000 - $8000. Large - scale, high - capacity industrial curing ovens, equipped with features such as automated conveyor systems and precise multi - zone temperature control, can have a cost exceeding $15000.

Prior to the utilization of the curing oven, it is imperative to preheat it to the requisite temperature in accordance with the instructions provided by the powder coating manufacturer. The powder - coated workpieces should be placed evenly within the oven, ensuring that they are not overcrowded to facilitate proper heat circulation. The curing time must be monitored closely, as different powder coatings have distinct curing requirements. Once the curing process is completed, the workpieces should be carefully removed using appropriate heat - resistant tools.

When the selection of a Powder Coating Curing Oven is under consideration, factors such as the size of the workpieces and the production volume must be taken into account. For small - sized workpieces and low - volume production, a benchtop or small - scale oven will generally suffice. For large - scale industrial production with high - volume requirements, a large - capacity oven equipped with an automated conveyor system is indispensable. Additionally, the required temperature accuracy for specific powder coatings should be factored in. The budget is another crucial determinant. A balance between requirements and cost should be struck to identify the most suitable oven.

Safety assumes the utmost significance during the use of a

Powder Coating Curing Oven. Heat - resistant gloves and safety glasses should be donned to safeguard against burns and potential splashes. It is essential to ensure that the oven is properly installed and grounded to avert electrical accidents. Overloading the oven should be avoided, as this can disrupt heat distribution and potentially pose a fire hazard. Regular inspections of the heating elements and the temperature control system should be conducted to detect any signs of malfunction.

The design of a

Powder Coating Curing Oven is highly rational. The precise temperature control system ensures the uniform curing of the powder coating, thereby resulting in a high - quality finish. The employment of efficient heating elements, whether electric or gas - fired, provides the necessary heat while keeping energy - efficiency in perspective. The conveyor system in continuous - type ovens enables a smooth and continuous curing process, thereby enhancing production efficiency.

Q: What measures should be taken if the powder coating exhibits bubbles post - curing?

A: Initially, the pre - heating process should be examined. If the temperature rises too rapidly, it may induce bubbles. Additionally, it is essential to ensure that the powder - coated workpiece is devoid of moisture prior to curing. The curing temperature and time should be adjusted in accordance with the powder coating specifications.

Q: Is it feasible to use a Powder Coating Curing Oven for different types of powder coatings?

A: Yes, however, it is imperative to clean the oven thoroughly between different powder types. Different powder coatings may have divergent curing requirements; thus, the temperature and time should be adjusted accordingly.

Q: How frequently should the temperature control system of the curing oven be calibrated?

A: It is recommended that the temperature control system be calibrated every 3 - 6 months, contingent upon the frequency of use. This ensures accurate temperature settings for consistent curing outcomes.

Q: What actions should be taken if the heating elements in the curing oven cease to function?

A: First, the power supply and the fuses should be checked. If they are found to be normal, the heating elements may have burned out. A professional technician should be contacted to replace the heating elements.

Q: Is it advisable to install a Powder Coating Curing Oven in a small, unventilated room?

A: It is not advisable. The curing process may generate fumes. The oven should be installed in a well - ventilated area or the room should be equipped with proper ventilation facilities to ensure safety.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com